Custom Hardwood Flooring

Houston's Best CustomHardwood Flooring Specialist

At Greater Houston Flooring we specialize in custom hardwood flooring. Custom hardwood flooring come in both solid, and engineered-unfinished plank. You will have your flooring raw, and unfinished. Once installed your flooring it is finished on site to any specification. The customer has full control of species of wood, colors, specialty treatments, and multiple finish options. There is nothing that matches the beauty of a custom hardwood floor.

Do you have question about Custom Hardwood Flooring? Call with any question you have!

Solid hardwood Flooring

Solid hardwood flooring is available in many species, grades, and sizes. We also offer antique, and reclaimed material options. Unlike an engineered product, solids must be installed over a wooden subfloor. When you install solid flooring over a concrete slab you are required to install a wooden subfloor over the concrete. This is done by two methods. We can install what is called a tar and screed subfloor. This type of subfloor consists of pouring hot mastic over the slab, and then laying screeds ( 1×4’s or 2×4”s) directly into the mastic. Another method is plywood, we use this method when installing wide with flooring in your home. Both methods allow us to be able to properly install your floor following national wood flooring association recommended installation procedure.

Some of the species we offer are: red oak, white oak, european white oak, french white oak, walnut, hickory, pine, american cherry, brazilian cherry, and maple. We have the ability to access many other species as well.

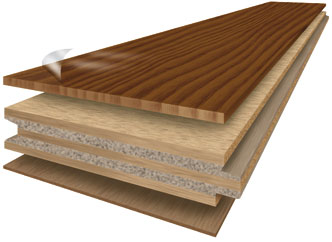

Engineered Unfinished Hardwood

Engineered unfinished flooring is a great choice when wanting a custom hardwood floor on your first floor concrete subfloor areas of your home. Due to its construction it is able to be glued directly to the slab, which allows for your flooring height to not be affected from the previous flooring. Due to its engineered construction, this type of product is ideal when a wide width floor is desired. Engineered unfinished flooring is more stable than solid. It will not expand and contract as much as a solid floor, giving you a much more stable floor. Engineered hardwood flooring is available in all species, grades, and sizes just like a solid. If you install an engineered unfinished on your first floor, and a solid on your second floor everything will match.

Engineered unfinished flooring is a great choice when wanting a custom hardwood floor on your first floor concrete subfloor areas of your home. This type of flooring is able to be glued directly to the slab, and these products are ideal when a wide width floor is desired. Engineered unfinished flooring is more stable than solid. It will not expand and contract as much as a solid floor, giving you a much more stable floor. Engineered hardwood flooring is available in all species, grades, and sizes just like a solid. If you install an engineered unfinished on your first floor, and a solid on your second floor everything will match.

From start to finish a custom hardwood floor will take approximately 3-4 weeks to complete. Custom hardwood flooring Installation usually takes about a week. After installation we allow your floor to acclimate to your home. Acclimation is the process of allowing your new flooring to equalize to the environmental conditions of your home. Therefore, after two to three weeks (in most cases) your floor is able to be safely finished. Moisture reading will be taken along the way to ensure that your floor is ready. After acclimation, we are ready to start the sand and finishing. Finishing process is typically completed in about a week when we are doing a standard finish job ( sanding, staining, and 2 coats of finish). Custom textures such as hand scraping, or wire brushing will add to the time of the project. European oil finishes will also add several days to the finishing process.

Solid hardwood flooring will be stapled to your wooden subfloor, and engineered will be glued to your subfloor using flooring adhesives. All of our floors will be installed with a moisture barrier system. Due to the proximity of Houston to the Gulf of Mexico we experience some of the highest humidity levels in the country. When installing a solid on a second floor area, we nail the flooring over premium underlayments. We offer noise reduction underlayment to reduce sound transfer from upstairs to downstairs.

The sand and finishing process is the final step of the project. With a custom hardwood floor the customer will select the desired color, and finish to be used. This is done during a color consultation while the sanding process has been started. This allows the customer to see the colors in their home. Paint color, and lighting play a large factor in the appearance of the flooring color so it’ best to make this decision in the home. When sanding in an occupied home, we will take the time to isolate the work areas from the rest of the residence to ensure dust containment to the best of our ability. Dust reduction systems will also be used on our equipment to eliminate up to 90% of airborn dust.

Finish Options

There are several finish options when installing a custom hardwood floor. We use oil modified polyurethane , water based urethane,

and Woca European Oil finishes.

Oil Modified Polyurethane

Commercial oil modified polyurethane is the standard finish material used on our site finished flooring. It has been used decades, and gives the floor great protection for years. Oil modified urethane is available in satin, semi-gloss, and gloss sheens. This finish is able to be walked on after 12-24 hours after application, and furniture can be moved onto the floor after 72 hours. We recommend allowing 1 week before installing rugs. Your oil modified finish will be fully cured in 14 days.

Water Based Finish

Water based finish has become very popular in recent years due to its strength, and being extremely environmentally friendly. Most water based finishes are zero voc. Unlike the oil modified polyurethanes, the water based can be walked on and recoated in 4-6 hours. Cure time is drastically cut as you floor will be fully cured in 72 hours, and furniture can be moved back into the home after 36 hours. Water base finishes are available in invisible/natural, matte, satin, semi-gloss, and gloss.

European Oil Finish

Greater Houston Flooring is a certified Woca European Oil contractor. Woca products are an environmentally safe plant based products. We are able to use reactive stains, and lyes to pre-treat your floor. Allowing you to achieve very different color profiles and effects not found in traditional finishes. European oil finished floors must be properly maintained, and when done on schedule this floor can go much longer between sand and finishes than a standard oil or waterbased polyurethane floor.

Custom hardwood floor repair it is a much more timely and costly procedure than with a pre finished hardwood floor. Occasionally scratches can be touched up, but they will almost always be able to be seen after the repair has been done. Sanding a spot is another option, but with this process the area repaired will be able to be seen as well. To ensure that the repaired area is not visible the entire floor must be sanded after the repair has been made.

Oil based polyurethane, and water based finishes can be damp mopped using bona floor cleaning kits. This is normally done every week or two.

European oil finished floors must be cleaned with a similar kit. It is important to follow the oil manufacturers recommended cleaning schedule to ensure the lasting durability of this finish type. With a woca oil finished floor the flooring will need to be cleaned with Woca soap every 2-4 weeks. The floor will need to have refresher applied every 3-4 months. We recommend having this process done by us. Every 1-3 years as the floor will need to have another coat of oil applied by your contractor.

Need A Free Estimate?

Free estimates on all Houston and The Woodlands Wood Floors!